Pts

As the water strain increases, it's transmitted evenly to the take a look at merchandise through the water, resulting in a uniform stress distribution across its floor. The take a look at strain must be a minimum of 1.1 and not extra than 1.3 instances the design stress of any system part. The pressure in the system ought to be progressively increased to 0.5 occasions the take a look at pressure, then enhance in 1/10th of the test strain increments until acquiring the appropriate check pressure. During the take a look at, a strain relief device with a set strain larger than the take a look at pressure but lower than the check stress must be used to stop permanent deformation of any system elements. Any item/part/component whose maximum permissible hydrostatic take a look at pressure is lower than the piping system is removed or isolated from pressure. Technicians install blind flanges, spade blinds, or closed position spectacle blinds to seal the system.

Filling And Venting

Our pump unit equipment complies with the necessities of the EU Strain Equipment Directive (PED). When adjustable pool floor add your hose and take a look at piece, the entire system must also adjust to the EU Stress Equipment Directive. Clearly testing a large quantity at very high pressure with a check fluid having a low ignition temperature has high risk. Hydrostatic testing is utilized in many industries—such as oil and fuel, manufacturing, marine, and development industries. This take a look at ensures that the equipment we are utilizing is completely secure and there is no risk of accidental failure or leak. In this text, we will let you know what's hydrostatic testing, how the Hydrostatic Take A Look At works, what its advantages are, and during which industries it is used the most.

Swimming Pool Enclosures

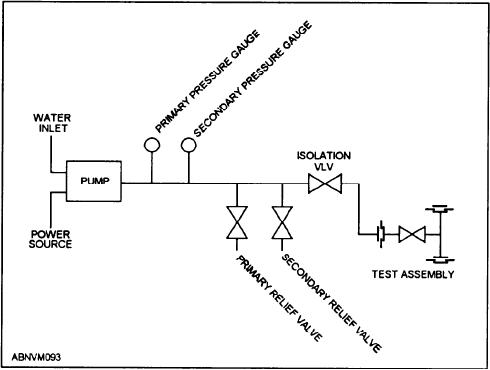

The aim of this method is to make certain that the take a look at item can withstand greater pressure than what it'll sometimes encounter during operation, providing an additional level of security. Hydrostatic testing should be carried out by certified and experienced technicians who are educated in the correct procedures and safety measures. The technicians should be geared up with the mandatory tools, similar to pumps, compressors, and stress gauges, and will comply with business requirements and laws. It can be essential to decide on a reputable and skilled testing company that has a confirmed track report of conducting correct and dependable exams.

Process For Hydro Testing

When water or one other liquid pressurizes the inside of the strain vessel during a hydro take a look at, the strain vessel might broaden or leak. Upon depressurization, technicians measure and note any everlasting deformation. modular movable pool floor isn't match for service if leaks are famous or everlasting deformation exceeds the specification. Hydro testing validates a vessel or equipment’s integrity by way of pressurized water. stainless steel pool floor of, a typical hydro-testing procedure, a hydro test chart, and applicable ASME and ASTM codes. Hydrostatic testing is a important safety procedure that helps stop accidents and environmental harm by ensuring that gear capable of working beneath strain is in good condition and meets security standards.

Hydrostatic Take A Look At

The strain shall then be lowered to the design stress earlier than analyzing for leakage. Throughout the test, a pressure aid system shall be provided, having a set pressure not greater than the take a look at pressure plus the lower of 345 kPa (50 psi) or 10% of the test stress. The pneumatic test stress shall not be lower than 1.2 nor more than 1.5 times the design strain of the piping system.

- Moreover, unbalanced water chemistry, notably improper pH levels, can result in the formation of scale and corrosion on pool covers and accessories.

- When water or one other liquid pressurizes the inside of the strain vessel throughout a hydro take a look at, the strain vessel may broaden or leak.

- A leak test is more usually carried out on an existing system to detect any leaks that may have developed over time.

- By understanding the various kinds of hydrostatic testing, its functions, and the physics behind the method, individuals can make knowledgeable choices about whether it is an applicable testing methodology for his or her wants.

- This check is carried out to ensure that the valve can face up to the utmost working stress and to determine any potential weaknesses earlier than the valve is put into service.

- It subsequently shall be decreased to the decrease design pressure or a hundred psig [700 kPa (gage)] and held for as lengthy as required to conduct the leakage examination.

- Some hydrostatic exams use a color tracer/ink in the water to boost the accuracy of a visible inspection.

Uk Pool & Spa Awards 2021 - Winner

When a container is filled with liquid, the pressure inside the container increases as the liquid is added. The amount of pressure exerted on the partitions of the container is set by the burden of the liquid and the depth of the container. As the stress is elevated, any weak factors in the container will start to indicate indicators of deformation, similar to bulging or cracking. By increasing the strain to a predetermined degree, the integrity of the container may be tested and verified. The strain shall be increased until a gage stress, which is the lower of zero.5 times the test pressure or 170 kPa (25 psi), at which period a preliminary check shall be made. Thereafter, the strain shall be steadily increased in steps until the strain is reached, holding the pressure at each step till the piping strains are equalized.

Aircraft Maintenance Help Benches

This commonplace specifies that the check pressure must be held for a minimal of 10 minutes for all valve sizes and kinds. It also defines the acceptance criteria for leaks, deformation, and other defects. The hydrostatic testing of pipelines ensures the structural integrity and leak tightness of the pipeline system. Common hydrostatic testing protects in opposition to catastrophic breakdowns and increases the life of kit. It not only ensures compliance with trade guidelines, nevertheless it additionally will increase confidence within the system’s reliability. MPI is appropriate for detecting cracks and other surface anomalies but, like radiographic and ultrasonic testing, does not assess strain integrity. Pneumatic testing makes use of air, nitrogen, or another gasoline as a substitute of water to pressurize the vessel or system. This methodology is particularly helpful when the check object can't be exposed to water or must be put back into service quickly after testing. Welding imperfections vary in impact from being acceptable to requiring restore. It is essential to ensure the quality of welds utilizing NDT and to ensure the power of the complete piping system with hydrotesting. In order to conduct a this methodology, the the vessel is full of water and loaded it right into a sealed chamber (called the check jacket) which can also be filled with water.